Joey Chin

Mechatronics Engineer

I make cars go fast and machines that build other machines

I make cars go fast and machines that build other machines

A mechatronics engineer with a passion for machine design and automotive electronics. I currently work at Robert Bosch (RBAU) where I provide engineering and production support in the Automotive Electronics/Semiconductor manufacturing department.

I intend to pursue a career in technical design, particularly within the fields of machine design, automation, robotics and automotive electronics.

I graduated with a Bachelor of Science in Mechatronic Systems from the University of Melbourne and am currently studying after work hours to complete a Master of Engineering (Mechatronics)

also at the University of Melbourne (expected mid 2021).

I have firsthand experience in the engineering design process, from problem formulation and requirements engineering to detailed design and final test/sign off.

I've been involved with FSAE for over 3 years and in this time have become highly

familiar with the design and integration of electromechanical subsystems within motorsport technologies.

In my role at Robert Bosch, I've also gained experience in process control/stability analysis and exposure to Siemens Simatic PLC programming.

Click the following sections to view my design portfolio

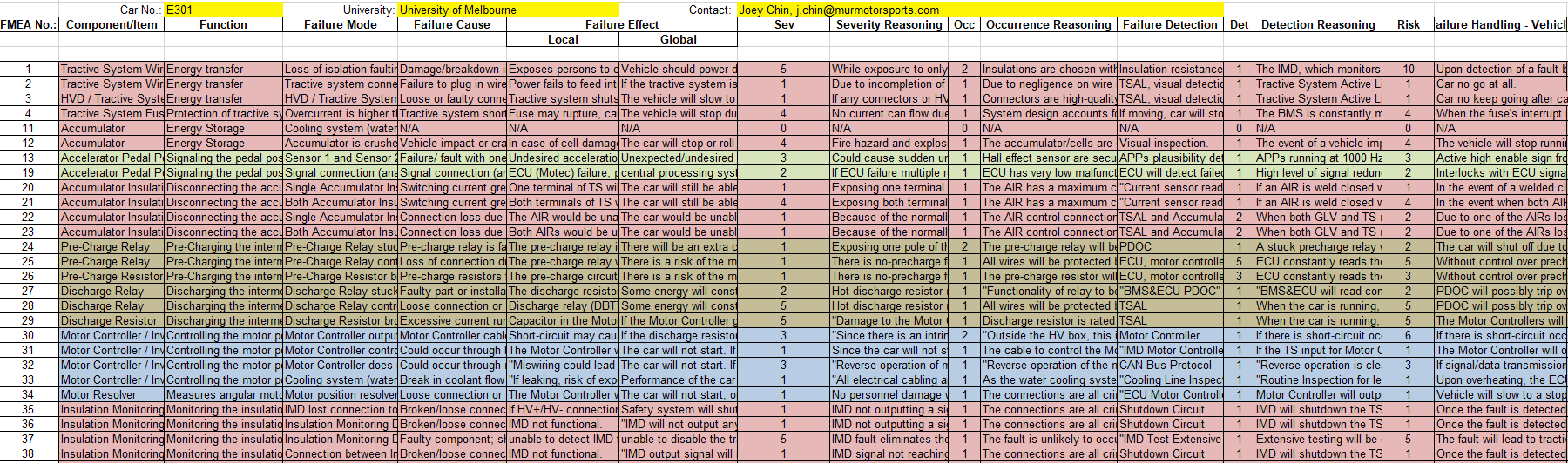

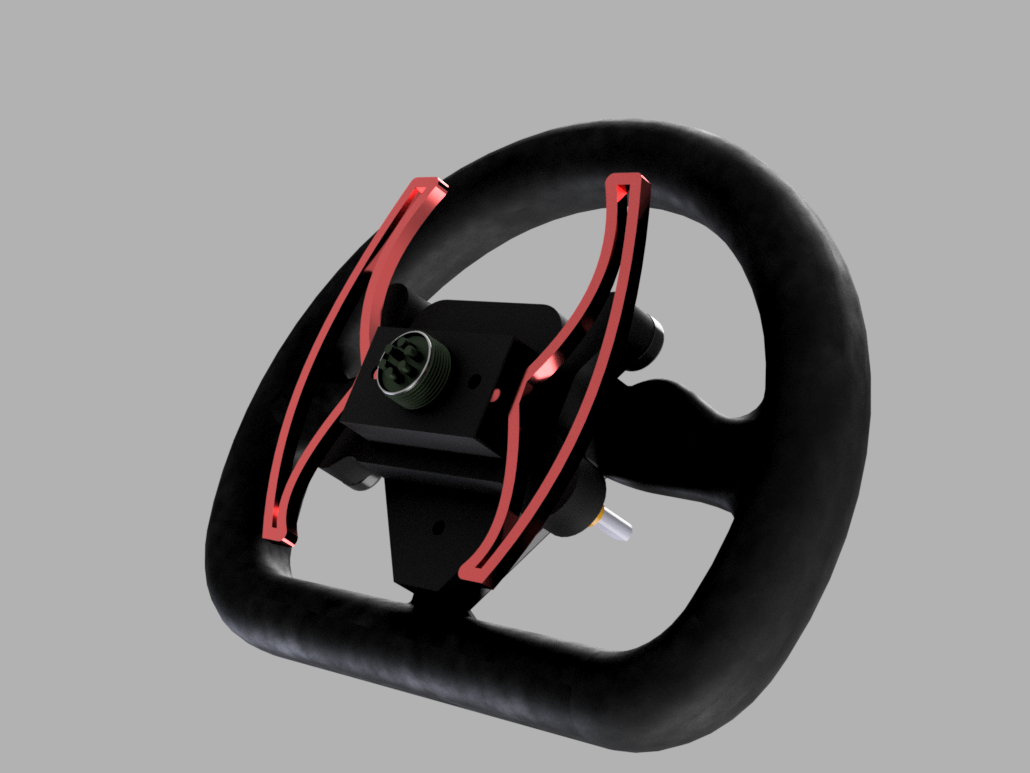

Formula SAE is an international competition where teams design, manufacture and run formula style race cars. After being part of MUR Motorsports for multiple years, I was given the opportunity to lead electrical powertrain development as the team's Chief Electrical Engineer.

My main responsibilities included

My main responsibilities included

This role required me to have a deep understanding of fundamental engineering and project management principles to drive development. A key focus was ensuring safe design and operation of the electric powertrain including a 400V accumulator and IGBT based dual inverters through FMEA.

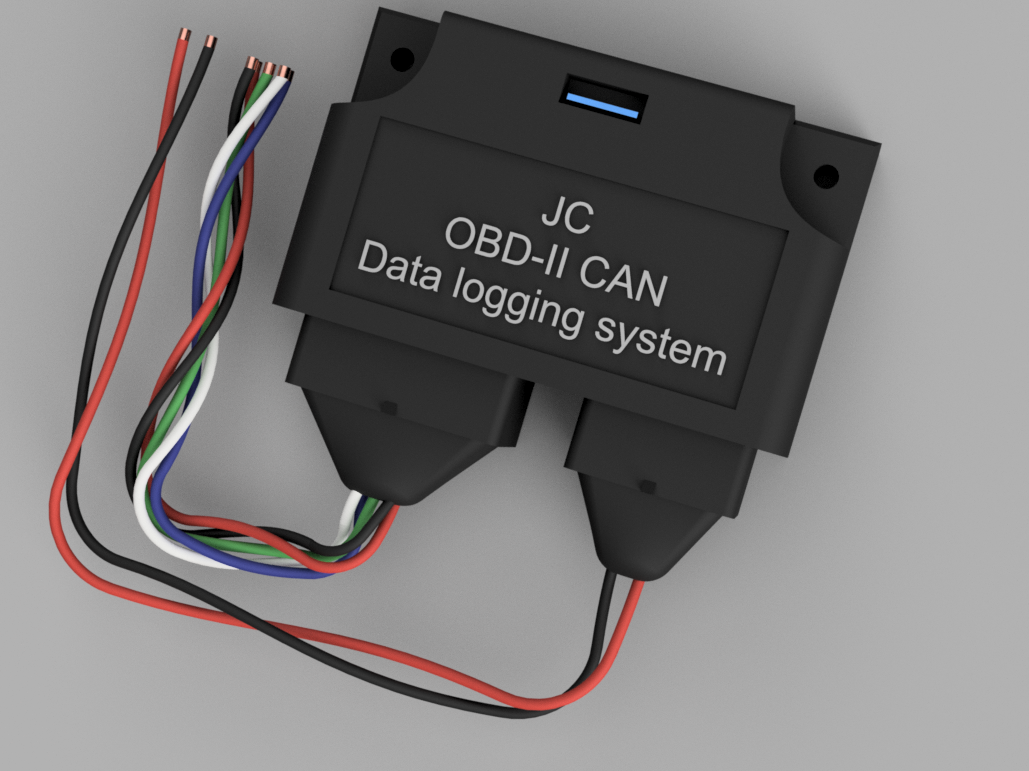

I have experience planning and building body harnesses for both traditional EFI street/track cars along with DIN-rail junction box style

harnesses for electric formula cars.

Along with this, I have designed and built the following.

I have a passion for machine design, I've always been fascinated with how things are made and the inner workings of industrial machines,

especially specialist production machines. The opportunity to work at Robert Bosch has allowed me to gain a deeper appreciation for

the design and operation of assembly lines.

I was also given the opportunity to automate a small business' production line for screen printing textiles.